Administrator

Administrator

- Thread starter

- #1

UPDATED WITH SUMMARY

Here is a summary of the specs revealed:

Inside Ford’s ‘Bounty' Culture: Why the UEV Platform Doesn't Need a Massive Battery

Up until the early 1970s, the automotive industry followed a single path for gas vehicles: More power meant a bigger engine, resulting in more weight, more cost, and, in most cases, worse fuel efficiency.

But then came the fuel crisis in the mid-1970s, which resulted in an innovative new device that could deliver both power and the fuel efficiency customers were suddenly demanding — the turbocharger. While the first automotive applications appeared in 1962 for racing, the technology truly began its journey toward the mainstream in 1973 with the debut of the BMW 2002 Turbo, proving that smaller engines could punch well above their weight.

It seemed to defy physics — using a new device that turned wasted energy into power for more compression to make a smaller engine behave like a much larger one. In 2011, Ford introduced its version of the turbo, EcoBoost, on the F-150 pickup truck in the U.S. Ford’s bet was that turbos would redefine the industry, including the F-150, even as others were skeptical of customer adoption.

Sales skyrocketed, and the industry followed suit: Now, nearly 75% of F-150 trucks are sold with turbocharged engines,1and nearly all our gas-powered vehicles offer it.

Today, the industry faces a similar challenge with electric vehicles, where the engineering solution for range anxiety has mostly been to increase the size of the battery in the vehicle. But the battery is the most crucial component to tackle affordability because it accounts for somewhere around 40% of the vehicle’s total cost and upwards of 25% of its total weight.

Just like when automakers simply made bigger engines, adding more battery makes the vehicle heavier, more expensive, and creates a massive physics challenge.

Our big bet for electric vehicles? Obsessing over the vehicle as a system to get more miles out of a smaller battery and radically simplifying the system to reduce the number of parts so we can deliver a new family of affordable electric vehicles to driveways around the world.

Hunting Trade-Offs with Bounties

Affordability is not a marketing tagline for us. To truly make vehicles built on this platform affordable, starting with a mid-size electric truck, we needed to hunt down the cost opportunities.

We started by creating a team within the skunkworks operation, tasked with developing range, efficiency, and performance metrics for priorities such as weight, drag and rolling resistance, and ultimately battery size. That team armed every engineer with a new way of evaluating tradeoffs — we call them bounties.

Historically, engineers in traditional automotive companies can be siloed in departments that match the component or system they are assigned to. They’re expected to advocate for the part they are working on while decreasing its cost, often without the context of understanding how it impacts the customer’s experience or performance of the vehicle.

For example, the aerodynamics team always wants a lower roof for less aerodynamic drag; the occupant package team wants a higher roof for more headroom, while the interiors team wants to decrease the cabin size to reduce the cost. Usually, these groups negotiate until they find a middle ground, one that inevitably ends in a tradeoff led by yet another department tasked with making tradeoffs on behalf of the customer.

Bounties change the negotiation, making the true cost of a tradeoff much clearer by connecting it to a specific value tied to the range and battery cost. Now, the aerodynamics team and interior team share the same goal, and both understood that adding even 1mm to the roof height would mean $1.30 in additional battery cost or .055 miles of range. With bounties, each team has a common objective to maximize range while decreasing battery cost — a direct linkage to giving our customers more.

This is just one example of countless bounties our team focused on. When we met targets, we would set more difficult ones to challenge ourselves further. One of these areas was our energy management system.

Smarter Energy Management, Built By Ford

An electrical architecture is the blueprint for how power and signals move through a product — what connects to what, how everything is controlled, and how it all works together reliably. Power conversion within an electric vehicle platform can account for a surprising amount of wasted energy in a vehicle while charging or even taking energy from the 400V battery and converting it to 48V for the low-voltage devices.

More importantly, it’s often segregated into functions that get sourced to external suppliers, each with their own enclosures, fasteners, and connecters, which drives high costs and excess weight into the platform.

So in 2023, we moved our high-voltage power electronics architecture and design for this platform in-house. With the acquisition of Auto Motive Power, or AMP, talented engineers joined our team with experience, pushing the limits of power conversion and energy management for numerous global electric vehicles already on the market today.

For the first time, customers will experience a fully electric vehicle charging ecosystem designed in-house by Ford using our own software. That means the hardware in the vehicle, including the bi-directional charging capabilities, comes from a team directly integrated into the one working on the platform and vehicle products. Customers will benefit from improvements that decrease the amount of time waiting around for the battery to charge, maximize the lifespan of the battery, and improvements in total cost of ownership.

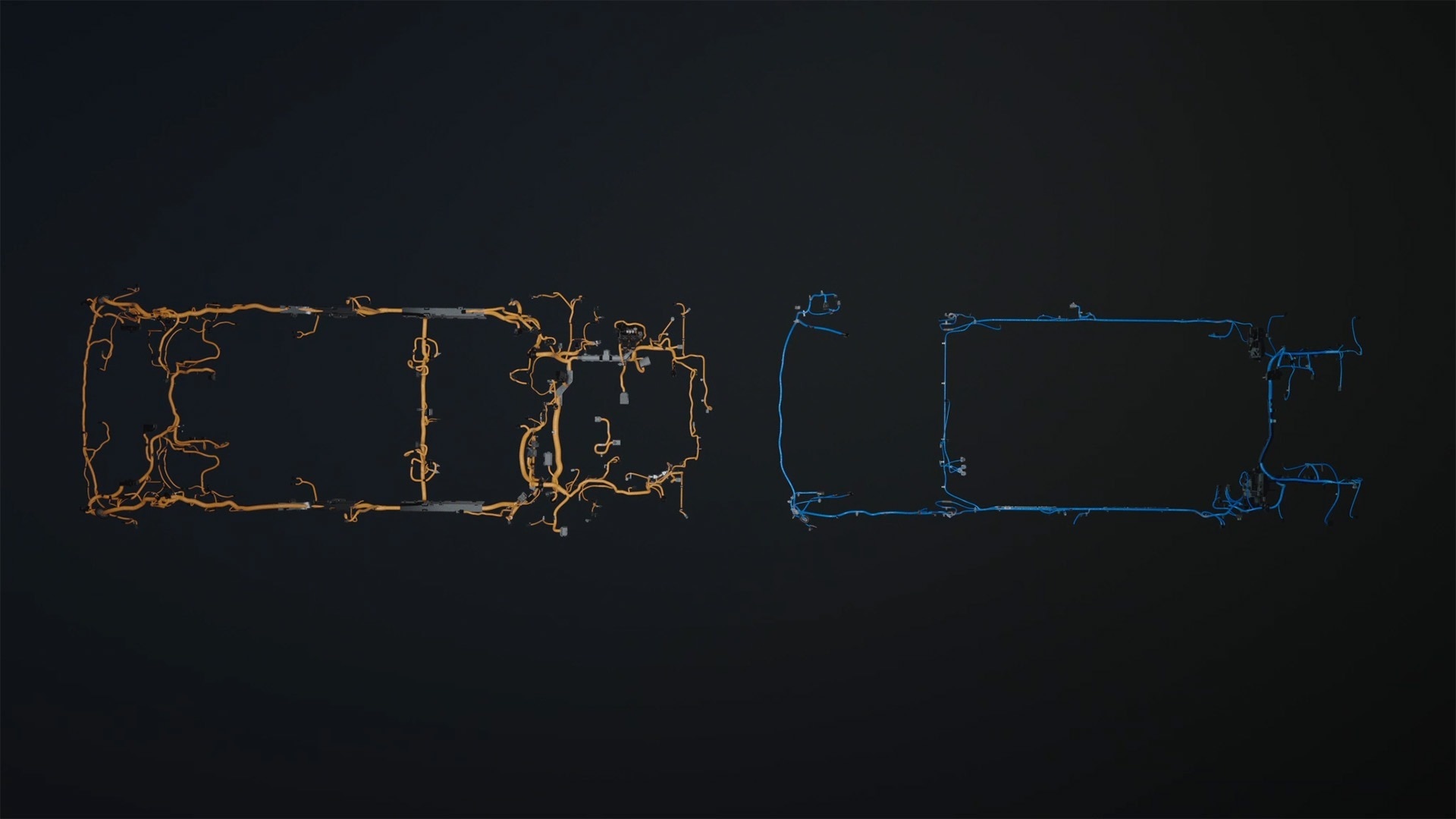

The team’s work has had profound improvements beyond just developing Ford’s first 48-volt low-voltage system. In fact, this new hardware and software have played a key role in making the mid-size electric truck's wire harness 4,000 feet shorter and 22 pounds lighter than one of our first gen electric vehicles.

We know there will be skeptics, just like there were when Ford introduced the turbo on the F-150. Other companies will claim that they've tried much of this before. But physics isn’t proprietary. We're creating a truly integrated electric vehicle platform, not a single part that can be easily copied.

If we succeed, we will have a family of vehicles that we expect to compete on price with the best in the world, including gas vehicles. There’s still a lot of work to do, but we’re making progress and we can’t wait to share more soon.

Here is a summary of the specs revealed:

- LFP battery (prismatic). Structural battery, a first for Ford. LFP Battery made in Michigan.

- New regen-braking design that saves $100 in battery cost.

- Ford says "if the same battery was married to the aerodynamics of the most aerodynamically efficient mid-size gas truck in the U.S., we believe our new electric truck would have nearly 50 miles or 15% more driving range. And a 30% improvement at highway speeds."

- Truck uses unicastings (gigacastings)

- Reduces parts by 20% versus a typical vehicle, with 25% fewer fasteners, 40% fewer workstations dock-to dock in the plant & 15% faster assembly time.

- Side mirror body size is 20% smaller than a conventional mirror, adding ~1.5 miles of range.

- New tire wake design: "We guided the front tire wake directly toward the rear tires, effectively "hiding" the rear wheels." This adds 4.5 miles of range.

- Wiring harness is more than 4,000 feet (1.3 kilometers) shorter and 22lbs kilograms lighter than the one used in their first-gen electric SUV.

- The new midsize truck is forecasted to have more passenger room than the latest Toyota RAV4, even before you include the frunk and the truck bed.

- The new midsize truck will have a targeted 0-60 time of 4.5s.

- Completely redesigned EV architecture

- Deliveries start in the U.S. in 2027 with a target starting MSRP of $30,000.

- https://www.fromtheroad.ford.com/us...-electric-vehicle-platform-battery-efficiency

- Ford is Not Backing Away from Electric Vehicles, We’re Democratizing Them: The industry is moving from electrification at any cost to electrification that scales. We’re meeting the market where it is by engineering a platform that will underpin a family of electric vehicles that are more affordable for more people starting with a mid-size electric truck in 2027. Affordability isn't a marketing goal -- it is an engineering output.

- Ford is Making its Universal Electric Vehicle Platform Low Cost by Focusing on Efficiency: To deliver a family of affordable high-tech electric vehicles that are fun to drive and can compete with the best electric vehicles on the global stage Ford hyper focused on overall efficiency including design and aerodynamics, engineering, battery management, software and production.

- You Don’t Need a Bigger Battery, You Need a More Efficient Vehicle: You don’t fix range with a bigger battery; you fix it with a more efficient vehicle. An electric vehicle’s most significant cost driver is the battery (40%+ of the total vehicle cost), so we designed a vehicle that simply needs less of it. Ford teams focused on reducing the size of the battery. We are solving the cost equation by chasing physics, not competitors.

Inside Ford’s ‘Bounty' Culture: Why the UEV Platform Doesn't Need a Massive Battery

Up until the early 1970s, the automotive industry followed a single path for gas vehicles: More power meant a bigger engine, resulting in more weight, more cost, and, in most cases, worse fuel efficiency.

But then came the fuel crisis in the mid-1970s, which resulted in an innovative new device that could deliver both power and the fuel efficiency customers were suddenly demanding — the turbocharger. While the first automotive applications appeared in 1962 for racing, the technology truly began its journey toward the mainstream in 1973 with the debut of the BMW 2002 Turbo, proving that smaller engines could punch well above their weight.

It seemed to defy physics — using a new device that turned wasted energy into power for more compression to make a smaller engine behave like a much larger one. In 2011, Ford introduced its version of the turbo, EcoBoost, on the F-150 pickup truck in the U.S. Ford’s bet was that turbos would redefine the industry, including the F-150, even as others were skeptical of customer adoption.

Sales skyrocketed, and the industry followed suit: Now, nearly 75% of F-150 trucks are sold with turbocharged engines,1and nearly all our gas-powered vehicles offer it.

Today, the industry faces a similar challenge with electric vehicles, where the engineering solution for range anxiety has mostly been to increase the size of the battery in the vehicle. But the battery is the most crucial component to tackle affordability because it accounts for somewhere around 40% of the vehicle’s total cost and upwards of 25% of its total weight.

Just like when automakers simply made bigger engines, adding more battery makes the vehicle heavier, more expensive, and creates a massive physics challenge.

Our big bet for electric vehicles? Obsessing over the vehicle as a system to get more miles out of a smaller battery and radically simplifying the system to reduce the number of parts so we can deliver a new family of affordable electric vehicles to driveways around the world.

Hunting Trade-Offs with Bounties

Affordability is not a marketing tagline for us. To truly make vehicles built on this platform affordable, starting with a mid-size electric truck, we needed to hunt down the cost opportunities.

We started by creating a team within the skunkworks operation, tasked with developing range, efficiency, and performance metrics for priorities such as weight, drag and rolling resistance, and ultimately battery size. That team armed every engineer with a new way of evaluating tradeoffs — we call them bounties.

Historically, engineers in traditional automotive companies can be siloed in departments that match the component or system they are assigned to. They’re expected to advocate for the part they are working on while decreasing its cost, often without the context of understanding how it impacts the customer’s experience or performance of the vehicle.

For example, the aerodynamics team always wants a lower roof for less aerodynamic drag; the occupant package team wants a higher roof for more headroom, while the interiors team wants to decrease the cabin size to reduce the cost. Usually, these groups negotiate until they find a middle ground, one that inevitably ends in a tradeoff led by yet another department tasked with making tradeoffs on behalf of the customer.

Bounties change the negotiation, making the true cost of a tradeoff much clearer by connecting it to a specific value tied to the range and battery cost. Now, the aerodynamics team and interior team share the same goal, and both understood that adding even 1mm to the roof height would mean $1.30 in additional battery cost or .055 miles of range. With bounties, each team has a common objective to maximize range while decreasing battery cost — a direct linkage to giving our customers more.

This is just one example of countless bounties our team focused on. When we met targets, we would set more difficult ones to challenge ourselves further. One of these areas was our energy management system.

Smarter Energy Management, Built By Ford

An electrical architecture is the blueprint for how power and signals move through a product — what connects to what, how everything is controlled, and how it all works together reliably. Power conversion within an electric vehicle platform can account for a surprising amount of wasted energy in a vehicle while charging or even taking energy from the 400V battery and converting it to 48V for the low-voltage devices.

More importantly, it’s often segregated into functions that get sourced to external suppliers, each with their own enclosures, fasteners, and connecters, which drives high costs and excess weight into the platform.

So in 2023, we moved our high-voltage power electronics architecture and design for this platform in-house. With the acquisition of Auto Motive Power, or AMP, talented engineers joined our team with experience, pushing the limits of power conversion and energy management for numerous global electric vehicles already on the market today.

For the first time, customers will experience a fully electric vehicle charging ecosystem designed in-house by Ford using our own software. That means the hardware in the vehicle, including the bi-directional charging capabilities, comes from a team directly integrated into the one working on the platform and vehicle products. Customers will benefit from improvements that decrease the amount of time waiting around for the battery to charge, maximize the lifespan of the battery, and improvements in total cost of ownership.

The team’s work has had profound improvements beyond just developing Ford’s first 48-volt low-voltage system. In fact, this new hardware and software have played a key role in making the mid-size electric truck's wire harness 4,000 feet shorter and 22 pounds lighter than one of our first gen electric vehicles.

We know there will be skeptics, just like there were when Ford introduced the turbo on the F-150. Other companies will claim that they've tried much of this before. But physics isn’t proprietary. We're creating a truly integrated electric vehicle platform, not a single part that can be easily copied.

If we succeed, we will have a family of vehicles that we expect to compete on price with the best in the world, including gas vehicles. There’s still a lot of work to do, but we’re making progress and we can’t wait to share more soon.